Pressure Transmitter

Pressure transmitters translate low-level electrical outputs from pressure sensing devices to higher-level signals that are suitable for transmission and processing. They are capable of performing various pressure measurements and displaying amounts in different units. Absolute pressure is a pressure measurement that is relative to a perfect vacuum. Typically, vacuum pressures are lower than the atmospheric pressure. Gage pressure, the most common type of pressure measurement, is relative to the local atmospheric pressure. By contrast, sealed gauge pressure is relative to one atmosphere of pressure (oz) at sea level. Differential pressure reflects the difference between two input pressures. Compound pressure instruments can display both positive and negative pressures.

Pressure Gauge

Bourdon tube pressure gauge

Bourdon tube pressure gauges are suitable for liquid and gaseous media, so long as they are not highly viscous or crystallising and do not attack copper alloy parts. The scale ranges cover pressures from 0.6 to 1000 bar.

These instruments are manufactured to EN 837-1 (Bourdon tube pressure gauges; dimensions, measuring technology, requirements and testing). For measuring points with high dynamic loads, such as fast load cycles or vibrations, a liquid-filled design should be used.

Diaphragm pressure gauge

The application areas for these gauges with diaphragm measuring elements, manufactured entirely in stainless steel, are aggressive gaseous and liquid media with open connection flanges, as well as highly viscous and contaminated media, also in aggressive ambience. They are suitable for scale ranges from 0 … 16 mbar to 0 … 40 bar. Dependant upon the pressure range and the instrument type, overpressure safety of up to a maximum of 3 x or 5 x full scale value is possible as standard, and for special designs,

10, 40, 100 or 400 bar, with the measuring accuracy maintained. Liquid filling the case ensures a precise instrument display, even with high dynamic pressure loads and vibrations. Special wetted parts materials are available as options.

Capsule pressure gauge

Capsule pressure gauges are particularly suited to very low pressures. The scale ranges lie between 0 � 2.5 mbar and 0 � 1000 mbar with an accuracy class of 0.1 to 2.5. Capsule pressure gauges consist of two circular, corrugated diaphragms, joined together around the edge with a pressuretight seal. These gauges are particularlysuited to gaseous media and relatively low pressures.

Overpressure protection is possible in certain cases. These pressure measuring instruments are used mainly within medical, vacuum, environmental and laboratory technology for contents measurement and filter monitoring.

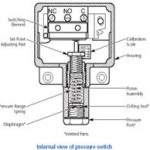

Pressure Switch

A pressure switch for sensing fluid pressure contains a capsule, bellows, Bourdon tube, diaphragm or piston element that deforms or displaces proportionally to the applied pressure. The resulting motion is applied, either directly or through amplifying levers, to a set of switch contacts. Since pressure may be changing slowly and contacts should operate quickly, some kind of over-center mechanism such as a miniature snap-action switch is used to ensure quick operation of the contacts. One sensitive type of pressure switch uses mercury switches mounted on a Bourdon tube; the shifting weight of the mercury provides a useful over-center characteristic.

The pressure switch may be adjustable, by moving the contacts or adjusting tension in a counterbalance spring. Industrial pressure switches may have a calibrated scale and pointer to show the set point of the switch. A pressure switch will have a differential range around its setpoint in which small changes of pressure do not change the state of the contacts. Some types allow adjustment of the differential.